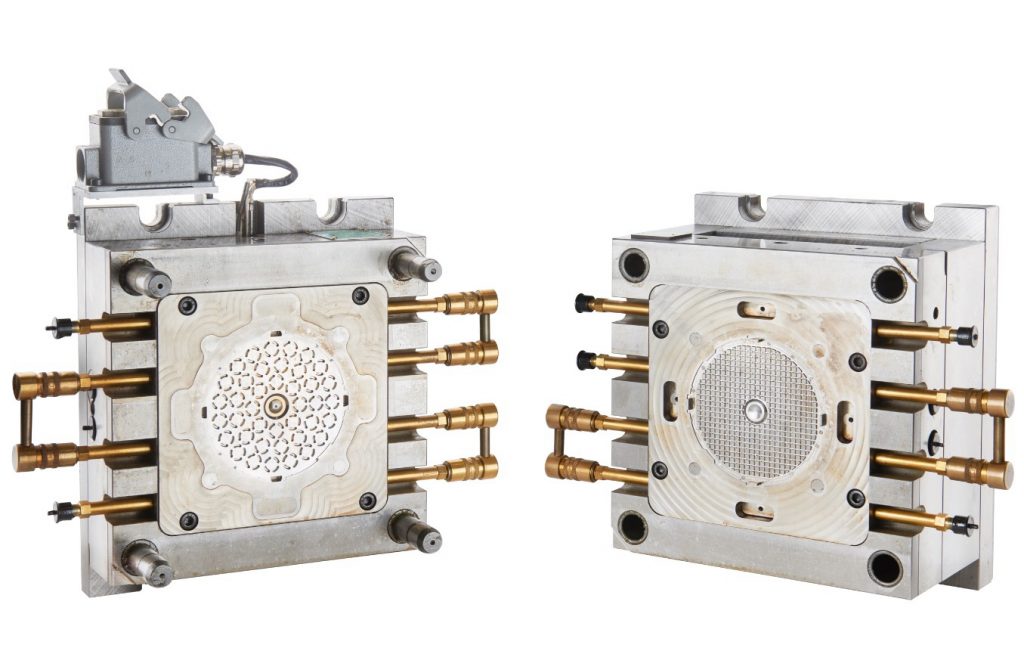

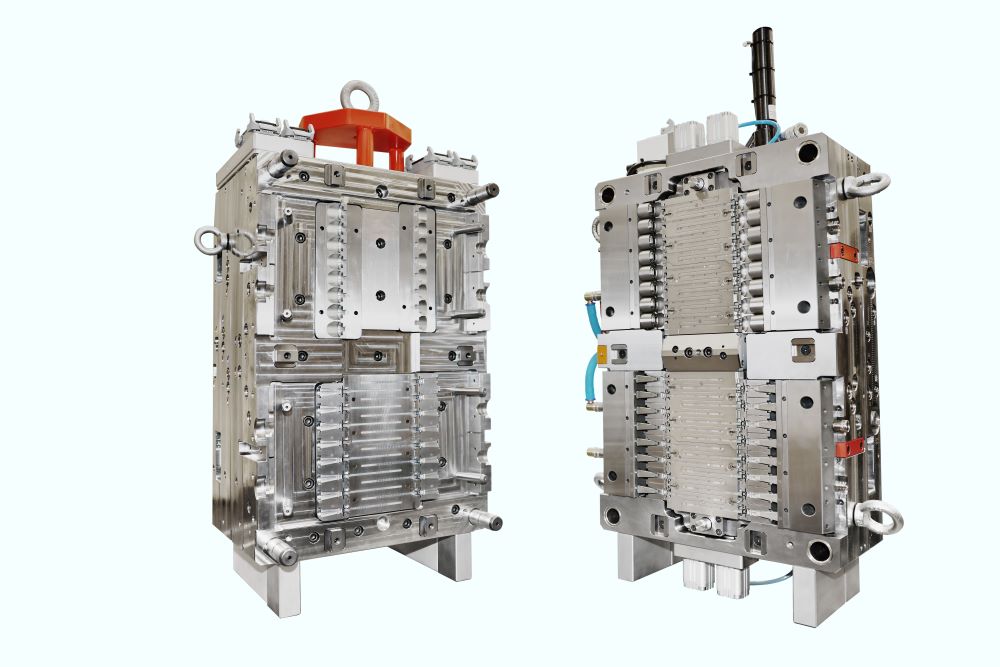

Mechanics – design and manufacture of tooling for plastics injection high precision moulds

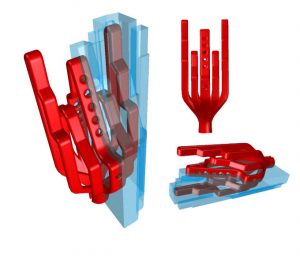

Thanks to our mechanical skills, we can design and produce high quality tooling and moulds. Upstream from actual production using injected plastic and rubber, our engineering department studies your project, advises and proposes solutions, produces sketches and 3D models, examines the rheology, and even designs the tools and injection mould required

With its mastery of the various precision techniques of plastics injection, our mechanics department guarantees the excellent quality of your tools and of your plastics our parts, even those with a shape of high complexity, from 1 to 48 cavities, in mono or multi-material, up to 2 tons.

• Conformal cooling, with 3D metal printing using laser fusion or additive manufacturing: by optimizing the material cooling time, this technique, which is mastered in-house, can meet quality requirements for complex and precise technical parts.

• To optimise your time to market, our tooling skills not only guarantee quality, but also increase our reactivity in the design, development, fine tuning and production of your injected parts.

• Our teams are ready to meet your challenges. A single contact person coordinates the various phases of your plastic parts project in terms of project management in APQP mode, the logistic support, the quality control, the maintenance, and the production.

Ask us for a quote or give us your ideas for series of all sizes. We will be happy to talk to you and make proposals. Contact form

Nos Marchés

Une compétence dans les pièces techniques de micro-précision au rendu esthétique de haut niveau.

Emballages inter opérations : des dizaines de paniers dans différentes matières et un accompagnement dans la rationalisation de vos flux.